Business cards

Work out how much cashback you could earn.

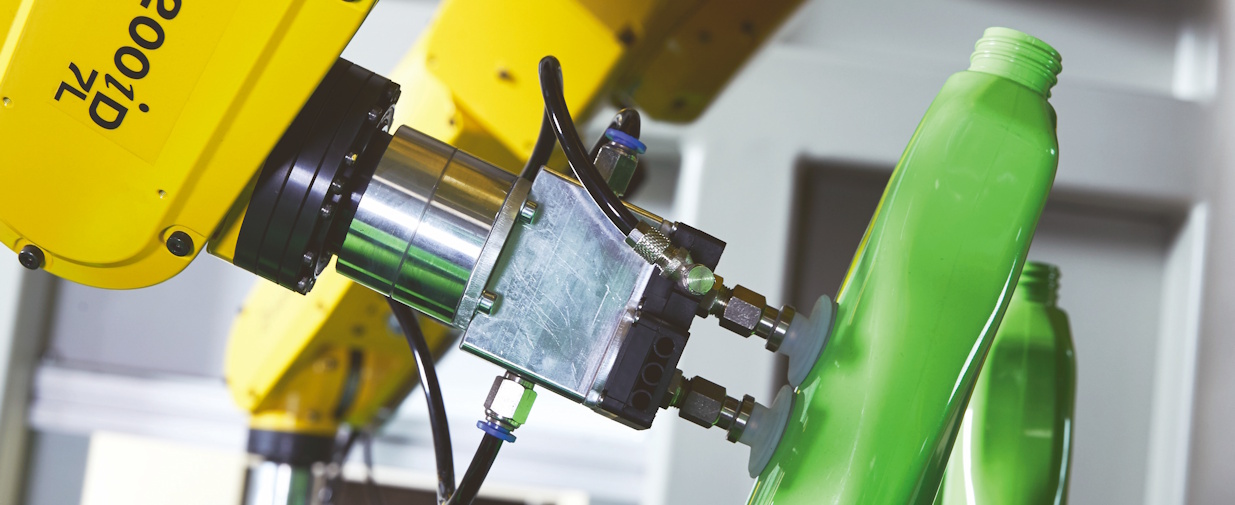

David Atkinson, UK Head of Manufacturing, SME & Mid-Corporates, considers how greater use of automation can make UK manufacturers more competitive, with insights from Mike Wilson, Chief Automation Officer at the Manufacturing Technology Centre.

Read time: 2 mins Added: 12/03/25

According to the latest available data from the International Federation for Robotics, the UK installed 3,830 industrial robots during 2023, which was an all-time high and an increase of 51% on the year before. That’s great news, but we still have a long way to go to catch up with our competitors.

The use of robotics and automation by UK manufacturers remains low compared to our competitors; Germany has around nine times as many industrial robots, while France has around double, despite its output being comparable to ours. And, though we are the world’s 12th largest manufacturing nation, we’re not even in the top 20 when it comes to robot use.

The UK’s historic aversion to automation is puzzling, especially as it is well understood to be a solution to one of manufacturers’ key challenges; improving productivity.

Robots can transform a business’ operations; enabling the better use of staff, existing machines and space, helping address recruitment challenges, creating more rewarding jobs, boosting yields and streamlining workflows.

Manufacturing often involves repetitive tasks, which colleagues find monotonous and demotivating, leading to quality issues and wastage. Automating time-consuming tasks like these creates consistency, which means less waste and improved efficiency, making manufacturers more sustainable. It also ensures colleagues are better utilised on tasks which add value.

Indeed, Mike Wilson says: “The effectiveness of a machine tool tended by a human operator is typically about 60-70%, while a machine tool tended by robot can be more than 90%.”

And robots are more accessible than they have ever been, even for the smallest manufacturers, with plug and play robots on the market that can be integrated into a production line for a relatively small outlay.

But manufacturers considering investing in automation must first do their due diligence; it's not quite as simple as just buying a robot to replace a human. That starts with strategically identifying those processes where automation can have the biggest impact.

If you aren’t sure where to start, the Manufacturing Technology Centre employs a team of experts who can visit your premises to carry out a free line walk, reviewing how you work and identifying opportunities to automate.

Mike Wilson says: “For firms investing in automation, there is a learning curve that means it is often better to start with a simple application rather than the biggest challenge on the shopfloor.”

Funding is available to support automation investment, including Hire Purchase and leasing products to help spread the cost and bring down barriers to entry. The real cost of automation is the cost of not doing it!